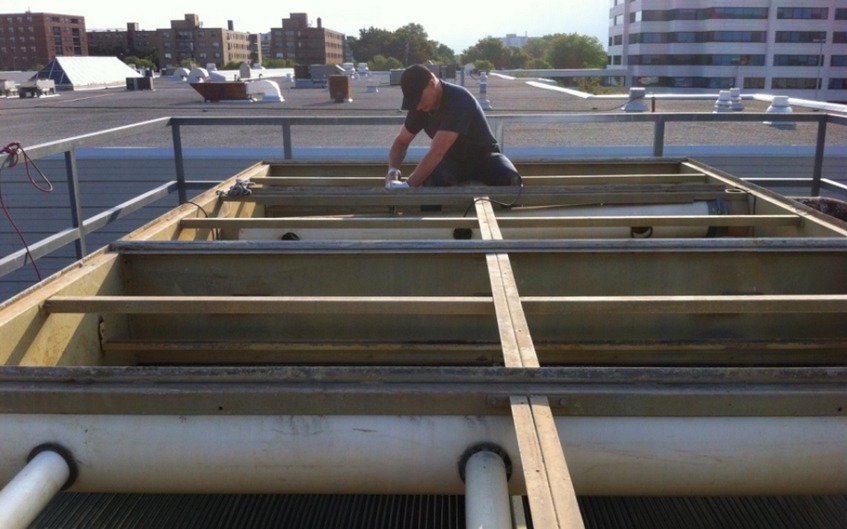

Customer was considering replacing this 1983 BAC Forced Draft cooling tower. The existing tower had the original corrugated fill media and the spray system had been upgraded with OEM medium sized spray nozzles.

The existing steel drift eliminators were coated with hard scale deposits and the interior of the tower had some corrosion evident in the cold water basin below the water line, the remainder of the interior casing panels were in excellent condition.

The fan shafts were corroded and the existing original single speed fan motors operated in conjunction with dampers within the fan housings to control leaving water temperature.

The drift eliminators were removed and cleaned in a bath of “RYDLYME” to remove all scale, rinsed and re-installed.

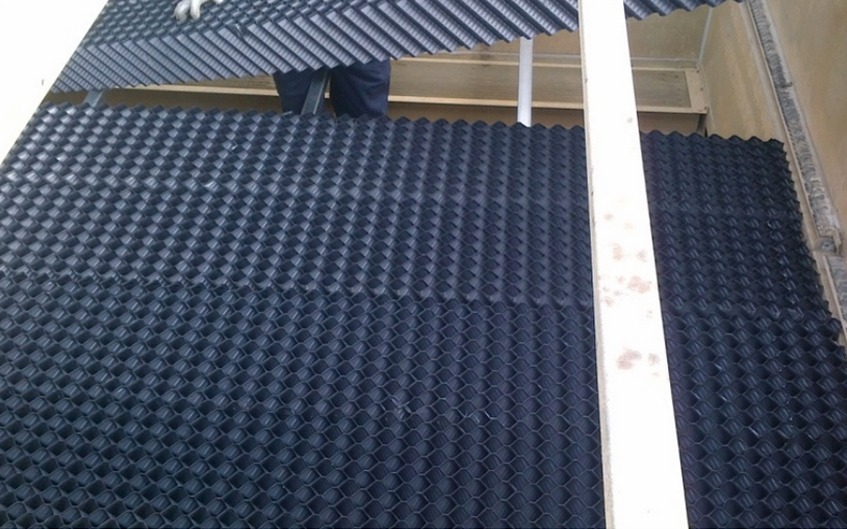

The existing obsolete corrugated fill media was removed and replaced with BRENTWOOD AccuPac® Cross-Fluted Fill which improves water distribution by splitting the water stream as it descends through the fill pack. Brentwood’s CF1900/CF1900MA design splits the water stream 8 times in a 12” (305 mm) vertical path.

High thermal performance (high KaV/L) and low pressure drop are achieved through engineered flute/microstructure design and the highest manufacturing standards.

The existing spray system which was completely plugged with debris and featured medium sized orifice nozzles was redesigned using BRENTWOOD dek-SPRAY large orifice non-clogging spray nozzles which produce a rectangular spray pattern, the dek-Spray nozzle is virtually maintenance free, since there are no moving parts used in its design. The branch arms were fitted for removable end caps to facilitate quick and easy cleaning of the system.

All interior seams were cleaned and caulked using polyurethane caulking and the cold water basin was mechanically cleaned and coated with a two part epoxy. The fan shafts were cleaned and bitumen coated for protection.

The existing fan motors were replaced with new high efficiency inverter duty motors and ABB Variable Frequency Drives to facilitate efficient and accurate condenser water temperature control.

New fan shaft bearings and vee belts were installed to complete this upgrade and the tower was re-commissioned.